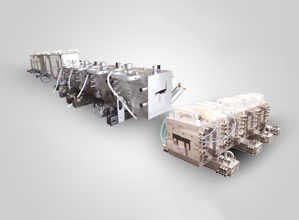

FSFC180 Auto Molding System

Publishdate:2024-09-12 Source: Views:1472

Product Introduction:

Mainly used for post-process packaging of IC, semiconductor device and substrates type. In addition to meeting the packaging requirements for FSAM series, it is particularly suitable for flip-chip type molding and multi-leads, high lead type molding.

Auto molding system includes loading unit, lead frame alignment unit, lead frame traction unit, lead frame preheating unit, resin supply unit, mechanical arm of loading and unloading unit, press unit, degating unit and product storage unit. Adopting gantry transfer loading unit to prevent LF shaking and warping during transfer.

Product Features:

◆ Max applicable L/F size: W100mm*L300 mm

◆ Adopts gantry transfer loading unit to prevent LF shaking and warping during transfer.

◆ Suitable for flip-chip type molding and multi-leads, high lead type molding.

Technical parameter

| Parameters of FSFC180 Auto Molding System | ||

| Name | Parameters | |

| L/F size | Width | 100mm |

| Length | 300mm | |

| Thickness | 0.1mm~2.0mm | |

| L/F Quantity/Shot | 2 pieces per mold | |

| Resin size | Resin diameter | 11mm--20mm |

| Resin length-diameter ratio | 1.1~1.7(Max35mm) | |

| Size of loading magazine placement area | 325mm | |

| System mechanical time | ≥28s | |

| Maximum clamping pressure (per unit) | 180T | |

| Maximum transfer pressure (per unit) | 4T | |

| Transfer stroke | ≥85mm | |

| Transfer speed | 0.1--20mm/sec | |

| 8stage speed regulation | ||

| Mold opening and closing speed | High speed140mm/sec | |

| low speed0.1--10mm/sec | ||

Product Introduction:

Mainly used for post-process packaging of IC, semiconductor device and substrates type. In addition to meeting the packaging requirements for FSAM series, it is particularly suitable for flip-chip type molding and multi-leads, high lead type molding.

Auto molding system includes loading unit, lead frame alignment unit, lead frame traction unit, lead frame preheating unit, resin supply unit, mechanical arm of loading and unloading unit, press unit, degating unit and product storage unit. Adopting gantry transfer loading unit to prevent LF shaking and warping during transfer.

Product Features:

◆ Max applicable L/F size: W100mm*L300 mm

◆ Adopts gantry transfer loading unit to prevent LF shaking and warping during transfer.

◆ Suitable for flip-chip type molding and multi-leads, high lead type molding.

Technical parameter

| Parameters of FSFC180 Auto Molding System | ||

| Name | Parameters | |

| L/F size | Width | 100mm |

| Length | 300mm | |

| Thickness | 0.1mm~2.0mm | |

| L/F Quantity/Shot | 2 pieces per mold | |

| Resin size | Resin diameter | 11mm--20mm |

| Resin length-diameter ratio | 1.1~1.7(Max35mm) | |

| Size of loading magazine placement area | 325mm | |

| System mechanical time | ≥28s | |

| Maximum clamping pressure (per unit) | 180T | |

| Maximum transfer pressure (per unit) | 4T | |

| Transfer stroke | ≥85mm | |

| Transfer speed | 0.1--20mm/sec | |

| 8stage speed regulation | ||

| Mold opening and closing speed | High speed140mm/sec | |

| low speed0.1--10mm/sec | ||

Contact us

Contact us