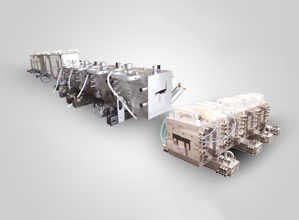

FSDM180 Dual Transfer Auto Molding System

Publishdate:2024-09-12 Source: Views:1483

Product Introduction:

Mainly used for the packaging of narrow products such as power devices and tantalum capacitors. It meets the packaging form of lead frames within 55mm * 300mm. It improves product quality and achieves stable mass production of a single product.

The system adopts a modular design and has a fully automatic device that integrates the auto loading of lead frame and resin, loading unit, unloading unit, press unit, mold and product auto degating and collection. It changes the previous single row transfer unit packaging form, adopts double row transfer units for packaging, realizes that one press can package 4 L/F. It doubles production capacity while reducing power consumption, labor demand, and site demand by half. This system is suitable for power devices, tantalum capacitors and other products.

Product Features:

◆Max applicable L/F size: W55*L300 mm;

◆By implementing a one-time 4-pieces packaging, power consumption, manpower requirements and site requirements are halved while doubling production capacity compared to FSAM equipment;

◆Suitable for narrow products such as power devices and tantalum capacitors, improving the packaging quality of such products;

◆Adopts gantry transfer loading unit to prevent LF shaking and warping during transfer.

Technical parameter

| Parameters of FSFC180 Double Injection Auto Molding System | ||

| Name | Parameters | |

| L/F size | Width | 55mm |

| Length | 300mm | |

| Thickness | 0.1mm~2.0mm | |

| L/F Quantity/Shot | 4 pieces per mold | |

| Resin size | Resin diameter | 12mm--20mm |

| Resin length-diameter ratio | 1.1~1.7(Max35mm) | |

| Size of loading magazine placement area | 550mm | |

| System mechanical time | ≥35s | |

| Maximum clamping pressure (per unit) | 180T | |

| Maximum transfer pressure (per unit) | 4T | |

| Transfer stroke | ≥85mm | |

| Transfer speed | 0.1--20mm/sec | |

| 8stage speed regulation | ||

| Mold opening and closing speed | High speed140mm/sec | |

| low speed0.1--10mm/sec | ||

Product Introduction:

Mainly used for the packaging of narrow products such as power devices and tantalum capacitors. It meets the packaging form of lead frames within 55mm * 300mm. It improves product quality and achieves stable mass production of a single product.

The system adopts a modular design and has a fully automatic device that integrates the auto loading of lead frame and resin, loading unit, unloading unit, press unit, mold and product auto degating and collection. It changes the previous single row transfer unit packaging form, adopts double row transfer units for packaging, realizes that one press can package 4 L/F. It doubles production capacity while reducing power consumption, labor demand, and site demand by half. This system is suitable for power devices, tantalum capacitors and other products.

Product Features:

◆Max applicable L/F size: W55*L300 mm;

◆By implementing a one-time 4-pieces packaging, power consumption, manpower requirements and site requirements are halved while doubling production capacity compared to FSAM equipment;

◆Suitable for narrow products such as power devices and tantalum capacitors, improving the packaging quality of such products;

◆Adopts gantry transfer loading unit to prevent LF shaking and warping during transfer.

Technical parameter

| Parameters of FSFC180 Double Injection Auto Molding System | ||

| Name | Parameters | |

| L/F size | Width | 55mm |

| Length | 300mm | |

| Thickness | 0.1mm~2.0mm | |

| L/F Quantity/Shot | 4 pieces per mold | |

| Resin size | Resin diameter | 12mm--20mm |

| Resin length-diameter ratio | 1.1~1.7(Max35mm) | |

| Size of loading magazine placement area | 550mm | |

| System mechanical time | ≥35s | |

| Maximum clamping pressure (per unit) | 180T | |

| Maximum transfer pressure (per unit) | 4T | |

| Transfer stroke | ≥85mm | |

| Transfer speed | 0.1--20mm/sec | |

| 8stage speed regulation | ||

| Mold opening and closing speed | High speed140mm/sec | |

| low speed0.1--10mm/sec | ||

Contact us

Contact us