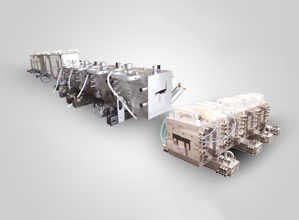

Wafer Level Packaging Equipment

Publishdate:2024-09-12 Source: Views:1517

Product Introduction:

Mainly used for advanced molding technology compression molding equipment for integrated circuits. It can realize two package forms of flange mold and full mold,suitable for package of liquid and granular resins, suitable for 8 inch, 12 inch, 320 diameter specification substrates.

This equipment includes press unit, filming unit, high vacuum unit and precision mold unit, as well as auto extrusion unit, powder spreading mechanism, and mold replacement special car.

Product Features:

◆Carrier: Maximum applicable 12 inches, 320 diameter

◆Adopting servo synchronous control technology, the consistency of the thickness of the package can be automatically adjusted

◆Suitable for compression molding package in wafer level WLP/panel level PLP and other forms。

Technical parameter

| Wafer level packaging equipment | |

| Name | Parameters |

| Wafer/carrier size | 12 inch/φ320mm |

| Wafer/carrier thickness | 0.4-1.5mm |

| Mold PKG thickness | 0.25 -2.1 mm/±15um |

| Mold-to-mold TTV over kit lifetime | ±15um |

| Molding Offset | ≤0.2mm |

| Cavity vacuum | <10Torr (within 2sec) |

| Molding chase temperature/accuracy | Max 190±3℃/±1℃ |

| Clamp Force | 80T/±1Ton |

| Closing Speed | Min. 0.01mm/s |

| Max. 36mm/s | |

| 10 steps | |

Product Introduction:

Mainly used for advanced molding technology compression molding equipment for integrated circuits. It can realize two package forms of flange mold and full mold,suitable for package of liquid and granular resins, suitable for 8 inch, 12 inch, 320 diameter specification substrates.

This equipment includes press unit, filming unit, high vacuum unit and precision mold unit, as well as auto extrusion unit, powder spreading mechanism, and mold replacement special car.

Product Features:

◆Carrier: Maximum applicable 12 inches, 320 diameter

◆Adopting servo synchronous control technology, the consistency of the thickness of the package can be automatically adjusted

◆Suitable for compression molding package in wafer level WLP/panel level PLP and other forms。

Technical parameter

| Wafer level packaging equipment | |

| Name | Parameters |

| Wafer/carrier size | 12 inch/φ320mm |

| Wafer/carrier thickness | 0.4-1.5mm |

| Mold PKG thickness | 0.25 -2.1 mm/±15um |

| Mold-to-mold TTV over kit lifetime | ±15um |

| Molding Offset | ≤0.2mm |

| Cavity vacuum | <10Torr (within 2sec) |

| Molding chase temperature/accuracy | Max 190±3℃/±1℃ |

| Clamp Force | 80T/±1Ton |

| Closing Speed | Min. 0.01mm/s |

| Max. 36mm/s | |

| 10 steps | |

- Prev:FSDM180 Dual Transfer Auto Molding System

- Next:None

Contact us

Contact us