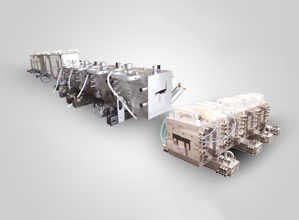

FSAM120 Auto Molding System

Publishdate:2024-09-12 Source: Views:1590

Product Introduction:

Mainly used for post-process packaging of IC, semiconductor device and substrates type. The main applicable product packaging forms are: SOP, SOT, SOD, SMA, SMB, SMC, DFN, QFN, QFP, BGA, CSP, PLCC, MCM, IGBT, IPM, LED substrate, etc.

This system includes loading unit, lead frame alignment unit, lead frame traction unit, lead frame preheating unit, resin supply unit, mechanical arm of loading and unloading unit, press unit, degating unit and product storage unit.

Product Features:

◆ Max applicable L/F size: W78mm*L260 mm

◆ Over a decade of experience and track record since its launch in 2007 (34% national market share in 2022)

◆ Provides the most cost-effective solution for common type products

Technical parameter

| Parameters of FSAM120 Auto Molding System | ||

| Name | Parameters | |

| L/F size | Width | 78mm |

| Length | 260mm | |

| Thickness | 0.1mm~2.0mm | |

| L/F Quantity/Shot | 2 pieces per mold | |

| Resin size | Resin diameter | 11mm--20mm |

| Resin length-diameter ratio | 1.1~1.7(Max35mm) | |

| Size of loading magazine placement area | 325mm | |

| System mechanical time | ≥28s | |

| Maximum clamping pressure (per unit) | 120T | |

| Maximum transfer pressure (per unit) | 3T | |

| Transfer stroke | ≥85mm | |

| Transfer speed | 0.1--20mm/sec | |

| 8stage speed regulation | ||

| Mold opening and closing speed | High speed140mm/sec | |

| low speed0.1--10mm/sec | ||

Product Introduction:

Mainly used for post-process packaging of IC, semiconductor device and substrates type. The main applicable product packaging forms are: SOP, SOT, SOD, SMA, SMB, SMC, DFN, QFN, QFP, BGA, CSP, PLCC, MCM, IGBT, IPM, LED substrate, etc.

This system includes loading unit, lead frame alignment unit, lead frame traction unit, lead frame preheating unit, resin supply unit, mechanical arm of loading and unloading unit, press unit, degating unit and product storage unit.

Product Features:

◆ Max applicable L/F size: W78mm*L260 mm

◆ Over a decade of experience and track record since its launch in 2007 (34% national market share in 2022)

◆ Provides the most cost-effective solution for common type products

Technical parameter

| Parameters of FSAM120 Auto Molding System | ||

| Name | Parameters | |

| L/F size | Width | 78mm |

| Length | 260mm | |

| Thickness | 0.1mm~2.0mm | |

| L/F Quantity/Shot | 2 pieces per mold | |

| Resin size | Resin diameter | 11mm--20mm |

| Resin length-diameter ratio | 1.1~1.7(Max35mm) | |

| Size of loading magazine placement area | 325mm | |

| System mechanical time | ≥28s | |

| Maximum clamping pressure (per unit) | 120T | |

| Maximum transfer pressure (per unit) | 3T | |

| Transfer stroke | ≥85mm | |

| Transfer speed | 0.1--20mm/sec | |

| 8stage speed regulation | ||

| Mold opening and closing speed | High speed140mm/sec | |

| low speed0.1--10mm/sec | ||

- Prev:None

- Next:FSAM180 Auto Molding System

Contact us

Contact us